How Adler Joailliers use titanium in their creations

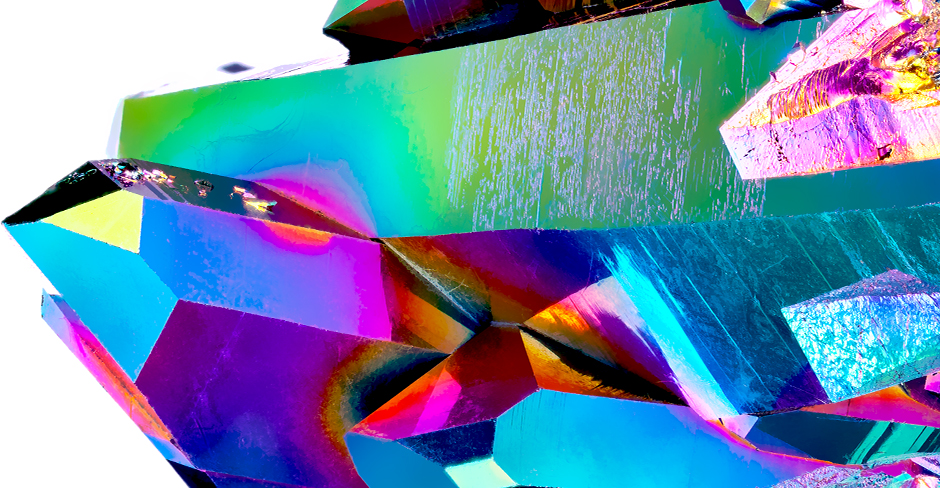

As a metal, titanium is harder to work than gold but its lightness makes it ideal for the creation of larger items of jewellery, particularly earrings, which remain very pleasant to wear regardless of their size. This metal opens new possibilities for designs that contain lots of precious stones. It has another characteristic that encourages creativity among more daring jewellers: it undergoes a long-lasting change of colour when subjected to an electrical current underwater. Depending on the voltage, titanium will acquire hues ranging from fuchsia to blue or bronze, and even a straw-coloured shade.

There are many meticulous stages involved in making titanium jewellery. On the basis of a drawing produced by hand in our design office, our teams firstly create a silver prototype which, little by little, reveals the jewel?s underlying nature and final appearance. From this silver prototype, a rubber mould is prepared into which wax is injected. The latter will be cast in plaster and finally replaced by molten metal.

Once the jewel has been removed from the plaster and its surfaces cleaned and pre-polished, precious stones are selected to be set in the piece. This crucial stage requires immense skill, since the stones are chosen one by one to create the best possible aesthetic balance. After being set with stones the piece is given a final polish. Next comes the process of anodizing, in other words modifying the colour of the titanium until the required shade is obtained. An extremely rigorous quality control is then naturally carried out before the new arrival can be offered for sale in Adler boutiques.

“We had to be ingenious for the Sail Collection. As it?s pretty big earrings, it had to be very light and comfortable to wear. That’s how we decided to use titanium, and became pioneers to use it in jewellery.” – Carlo Adler.